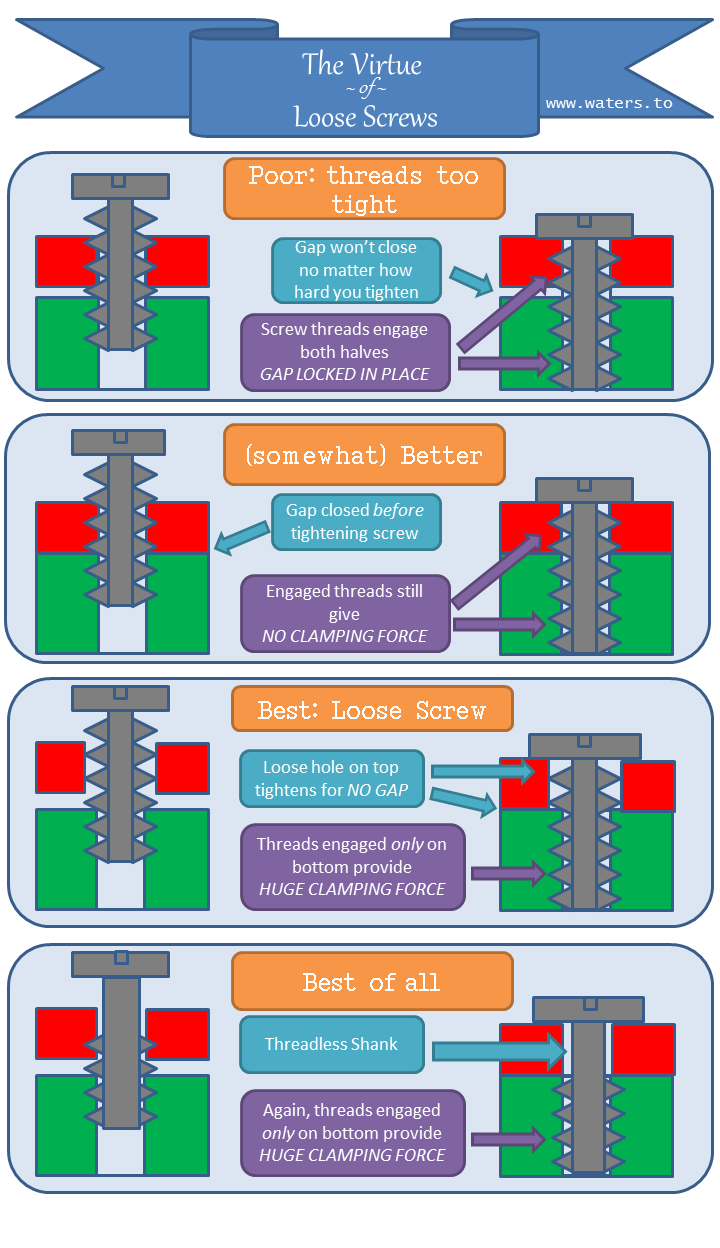

Fastening two pieces of wood together with a screw seems like such a simple thing, and yet most people (myself included, until recently) never learn to do it properly. The counterintuitive lesson I have learned is very simple:

Loose Screws Make Tight Joints

That is to say, pre-drilling ONE loose screw hole allows the screw to draw the joint tight with a great deal of clamping force, even if you start out with a gap between the boards. On the contrary, if the top screw hole is tight, allowing the screw to bite into the top piece of wood, any gap — regardless of how small — will be locked in place and the boards will never draw tight.

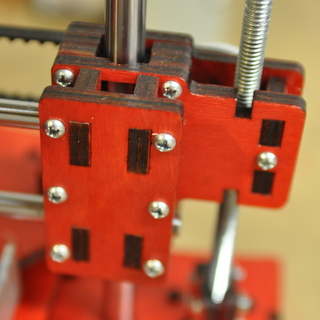

Printrbot Z-Axis Carriage. I drilled out some of the laser cut holes to better allow these screws to draw tight

I was reminded of importance of this technique recently, as I assembled my Printrbot 3D printer kit. The Printrbot kit consists of many pieces of laser-cut wood that MUST be tightly screwed together tightly using the technique above.

Failure to do so can turn this sturdy machine, capable of epic 3D-printing awesomeness, into a wobbly maker of not-so-epic “abstract plastic blob art”.