Several of my recent design projects have required properly-fitting o-rings, and yet as I looked around the web, I was frustrated at my inability to find a good practical explanation of their use.

Which size o-rings fit with which size pipes? Which pipe sizes nest closely?

After much experimenting with various PVC fittings, copper fittings, and o-rings of all assortments, I have a few answers that I outline here my own mini-guide to the use of O-rings in PVC/CPVC projects.

Nominal vs Actual Pipe Diameter

Any discussion of O-rings needs to start with a discussion about pipe diameter.

In the United States, pipe and tubing is generally specified as a “nominal” size in imperial units, for example 1/2″ copper tubing or 3/4″ PVC pipe.

In much the same way that “two by four” lumber doesn’t actually measure 2 inches by 4 inches, a 1/2″ pipe has neither an inner nor outer diameter of 1/2″. Nominal 1/2″ copper pipe has an ACTUAL outer diameter of 0.875 inches.

Outside Diameter (OD)

Pipe sizes are specified in terms of their nominal outside diameter, also known as “OD”. The OD of 1/2″ PVC pipe from any manufacturer will always be within a fraction of a millimeter of the defined standard for PVC pipe.

Of course, since the outside diameter of a pipe mates up with the inside diameter (“ID”) of a fitting like a coupler or a tee, the ID of a 1/2″ fitting from any manufacturer will also be effectively constant.

This brings us to:

Design Rule 1 for O-rings: Any measurement that requires a close tolerance should be made relative to the OUTSIDE diameter of a pipe, or the INSIDE diameter of a fitting.

Inside Diameter (ID)

The wall thickness and inside diameter of pipes is generally NOT specified. Due to the properties of the material, wall thickness generally falls in a narrow range, but it is very common to see differences between pipe made by different manufacturers, and even across lots from the same manufacturer. Similarly, the wall thickness of a fitting like a coupler or tee is not specified, and varies widely from part to part.

This brings us to:

Design Rule 2 for O-rings: Joints that depends on the INSIDE diameter of a pipe or the OUTSIDE diameter of a coupling are not guaranteed to work (since their size is manufacturer dependent)

Across materials, 1/2″ pipe does not always match 1/2″ pipe, but 1/2″ thread always mates with 1/2″ thread

As if nominal vs actual measurements weren’t bad enough, the ACTUAL diameter of 1/2″ copper tubing is NOT the same as 1/2″ PVC. See the table below for a listing of common pipe materials and their associated sizing specs.

One saving grace: The guys who set the specs for pipe threads seemed to have their act together, so 1/2″ threads are 1/2″ threads, whether you are talking copper, PVC, CPVC, etc.

Copper Tubingreddish brownSched. 40 Copperhot and cold water plumbingComes in different grades, but all have the same outside diameter

| Material | Color | Sizing Standard | Uses | Notes |

|---|---|---|---|---|

| PVC – Schedule 40 | White | Sched. 40 PVC | cold water plumbing | Not to be confused with DWV PVC – see below |

| PVC – DWV | White | Sched. 40 PVC | drains | DWV stands for drain-waste-vent. It generally has a thin wall ans is not suitable for holding pressure |

| CPVC – CTS | Yellowish white | Sched. 40 Copper | Hot and cold water plumbing | Very useful in o-ring applications due to its unique sizing. Not to be confused with schedule 80 CPVC which is typically dark grey and uses its own sizing standard. CPVC CTS is becoming harder to find as PEX rises in popularity |

| PEX | Varies, commonly red, white, and blue | Schedule 40 copper | hot and cold water plumbing | Rapidly replacing CPVC CTS in many applications |

O-Ring Sizing

O-rings specs are generally sized based on “nominal” inner diameter, outer diameter, and cross-section. This “nominal” measurement should not be confused with “nominal” pipe size. A “nominal” 5/8″ ID O-ring has an ID of just about 5/8″, plus or minus the manufacturing tolerance.

Many common O-ring sizes have a sort of shorthand name, colloquially called a “dash” number. For example, a “-212” (“dash two twelve”) O-ring has an ID of 5/8″, a cross section of 1/8″, and therefore an OD of 7/8″.

Useful O-Ring sizes

| Dash Number | ID | OD | Notes | Where to buy |

|---|---|---|---|---|

| -208 | 5/8 | 7/8 | fits over 1/2″ copper, inside 3/4″ copper fitting | Amazon |

| -212 | 7/8 | 1 1/8 | fits over 3/4″ copper, inside 1″ copper fitting | Amazon |

Note: It supports my O-ring habit when you buy through the links above.

O-Ring Recipe for 1/2″ copper or CTS CPVC

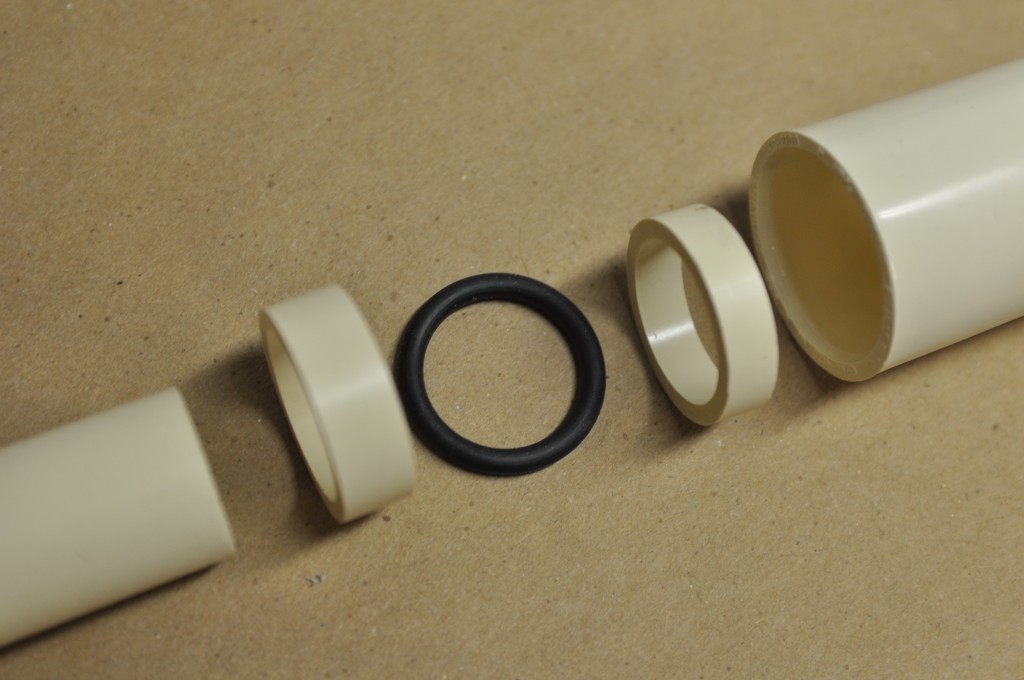

By happy circumstance, 1/2″ CTS CPVC fits neatly inside 3/4″ CPVC, and a -208 O-ring is perfectly matches the OD of each.

| Item | ID | OD | Notes |

|---|---|---|---|

| 1/2″ CPVC pipe | – | 5/8″ | |

| Sliver of 3/4″ CPVC pipe | unspecified, but larger than 5/8″ | 7/8″ | Glued inside the 3/4″ fitting, this serves as the outer O-ring retainer |

| -208 O-ring | 5/8″ | 7/8″ | |

| Sliver of 3/4″ CPVC pipe | unspecified, but larger than 5/8″ | 7/8″ | Glued inside the 3/4″ fitting, this serves as the inner O-ring retainer |

| 3/4″ CPVC fitting | 7/8″ | Cement the two slivers of 3/4″ CPVC inside to form a groove for the O-ring |

O-Ring Recipe for 3/4″ copper or CTS CPVC

This is really just the 1/2″ recipe, with all elements bumped up by one size — 1/2″ becomes 3/4″, 3/4″ becomes 1″, -208 ring becomes -212

By happy circumstance, 3/4″ CTS CPVC fits neatly inside 1″ CPVC, and a -212 O-ring is perfectly matches the OD of each.

| Item | ID | OD | Notes |

|---|---|---|---|

| 3/4″ CPVC pipe | – | 7/8″ | |

| Sliver of 1″ CPVC pipe | unspecified, but larger than 7/8″ | 1 1/8″ | Glued inside the 1″ fitting, this serves as the outer O-ring retainer |

| -208 O-ring | 7/8″ | 1 1/8″ | |

| Sliver of 1″ CPVC pipe | unspecified, but larger than 7/8″ | 1 1/8″ | Glued inside the 1″ fitting, this serves as the inner O-ring retainer |

| 1″ CPVC fitting | 1 1-8″ | Cement the two slivers of 3/4″ CPVC inside to form a groove for the O-ring |