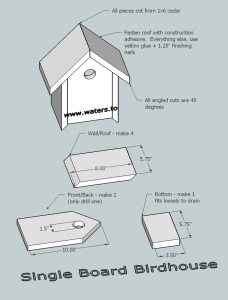

A few years ago, I made about a dozen birdhouses and gave them out as gifts. I was recently asked for the plans, and had to admit that there were none — I pretty much made everything up on the fly. Pictured is my attempt at retroactive plans drawn from memory…

A few years ago, I made about a dozen birdhouses and gave them out as gifts. I was recently asked for the plans, and had to admit that there were none — I pretty much made everything up on the fly. Pictured is my attempt at retroactive plans drawn from memory…

Construction is very easy:

– The entire birdhouse comes from a single 1×4 or 1×6

– All cuts are for length only – no ripping required

– All angled cuts are 45 degrees.

The design is very forgiving with respect to dimensions, so a hand saw would work just fine if you don’t have access to a miter saw.

The only real trick is securely attaching the roof, since it is difficult to fasten to the end-grain of the sides. If I were making them again, I’d use a construction adhesive like PL Premium which works well in that situation.

Click the image above to enlarge, or you can see the raw plans in Sketchup format here: Birdhouse Plans in Sketchup Format